The strategic importance of containers for supply chains operations

27/06/202340-foot shipping containers have been a crucial component of global logistics for decades due to their relevance in transporting maritime cargo from Asian ports to any other area of the world. In recent years this dynamic has been changing to work with a nearshoring model, as working with nearshoring vs offshoring models offers advantages for ensuring supply chains will not break up. But containers are still an important way to move shipments for maritime and logistics operators.

A 40-foot container is 40 feet long (12.192 m), 8 feet wide (2.438 m), and 8 feet with 6 inches high (2.591 m), with nearly 2,300 ft3 (68 m3) of internal space, which allows this structure to hold the contents and belongings f a 3 or 4-bedroom family home, 3 or 4 cars, or around 400 mattresses. This capacity is the reason why 40-foot shipping containers are used, not to mention that the port's infrastructure (tows, forklifts, and port machinery) is generally adapted to these sizes and the 20-foot shipping containers.

Tariffs as a key factor for shipment way decisions

War, as in many different cases, was a key factor in the standardization of structures for cargo shipments. It was the US Army during World War II that explored the use of small containers to transport guns, bombs, and other materials.

In the 1950 decade, American entrepreneur Malcolm McLean realized that standardizing the containers could help improve ships and trains’ load and unload times in transport operations. In 1956, he created the standard cargo container, which was 33 feet long and soon was improved to 35 feet long.

Using standardized containers reduced the cost of loading and unloading ships from US $5.86 each ton to US $16 cents for each ton, changing how global commerce operates and improving the protection for goods that must be transported.

Main types of containers used in maritime and train transport

The 40-foot and 20-foot shipping containers are the standard for moving multiple kinds of products in ships around the world, but there are also 10-foot and 30-foot containers. It’s noticeable that for each measurement, there are different types:

Dry Van container

The most used for the transport of goods by sea. It’s designed in an airtight and non-ventilated manner, and it’s recommended for transporting dry goods. Dry Van containers can be stacked up to 8 levels, allowing a large loading volume.

Dry Van Container

High Cube container

It has a very similar design to a Dry Van container, but it’s 2.89 meters in height, compared to 2.6 meters of Dry Van containers. These allow High Cube containers to transport loads with larger dimensions and large volumes.

High Cube Container

Open Side container

With the same design as Dry Van containers, it has 4-wing doors to allow the easier shipment of goods for loading and unloading functions.

Open Side Container

Open Top container

It has a similar design to the Dry Van container, but it doesn’t have a roof, which facilitates loading and unloading from the top of the container, making it easier to handle heavy goods. The unroofed top is generally covered with a tarp securely fastened to the container’s body.

Open Top Container

Flat Rack container

It’s used for machinery or automobile transportation. It has no roof or side walls, facilitating the loading and unloading of goods.

Flat Rack Container

Refrigerated container

A type of container designed to transport goods that require temperature control. It can maintain temperatures from -30°C to 40°C, and some models can reach -60°C.

Refrigerated Container

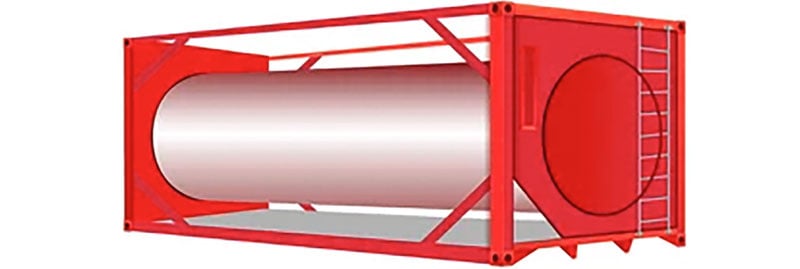

Tank container

It resembles a tank with the dimensions of a standard container. It’s designed to store liquid goods and facilitates loading and unloading.

Tank Container

Railways integration and a major diversity of containers

There are also various options for diverse goods when transporting different articles in ground infrastructure, such as railways. The main containers and features we can mention are:

Platform Cart or Utility Cart

It consists of a floor extending over a sideless support designed to transport large-sized products.

Utility Cart

Tanker Truck

Tank Cars or Tanker Trucks are used exclusively for transporting liquids, liquefied gases, compressed gases, and liquefied solids before unloading. Generally, train companies do not provide these cars, which are the property of different enterprises.

Tank Car

Train companies should require that tank cars comply with safety standards described in specifications developed by different countries where they have operations. Mexican standards are guided by the Tank Car Safety Standards (Specifications) issued by the U.S. Department of Transportation and the Canadian Department of Transportation for tank cars carrying flammable liquids (Class 3 risk classification) and toxic inhalation hazards (TIH).

Gondola Rail Cars

Gondola cars are rail cars with an open top and fixed sides, either fixed or hinged ends, and solid bottom surfaces. Equipped gondola cars have special features designed to transport specific products ranging from aggregates and minerals to metals and waste.

Gondola Rail Car

Automotive Rail Cars

With 2 or 3 levels and the capacity to transport from 10 to 24 automobiles, Automotive Rail Cars are designed to transport all the items the automotive industry needs promptly.

Automotive Rail Car

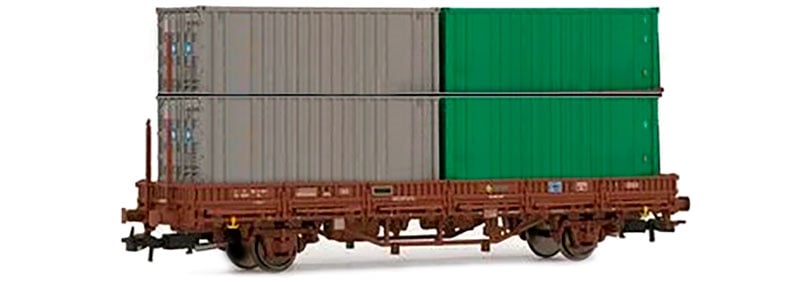

Intermodal container

Intermodal equipment allows shippers to transport cargo by rail, truck, or ship using the same shipping container.

Intermodal Container

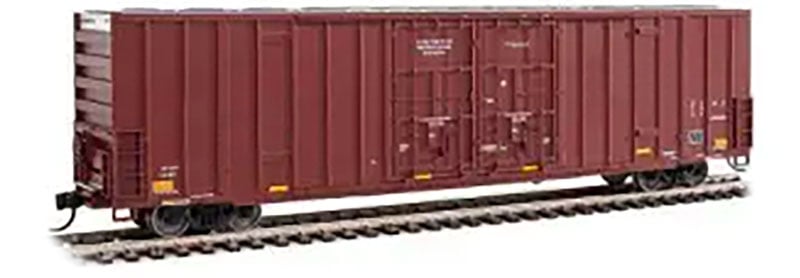

Boxcar

The boxcars are completely enclosed with doors. Equipped boxcars have special conditioning that facilitates the transportation of products ranging from appliances to paper.

Boxcar

Covered Hopper

Covered hoppers are closed and are used for bulk loads. They are equipped with tight-fitting top loading hatches and are typically used with grains and agricultural products.

Covered hopper for grains

Covered Hopper for minerals

.jpg?width=800&height=268&name=Blog-Contenedores-tolva-granelera-mineral-Frontier-Jun23%20(1).jpg)

Covered hopper for cement

A standardized code for effective operations

The 20-foot container, with a maximum weight of 18 tons, is referred to as a TEU (twenty-foot equivalent unit), while the 40-foot container is designated as 2 TEUs or 1 FEU (forty-foot equivalent unit). Most of them are made of corten steel, which protects them from atmospheric corrosion.

Containers typically have moisture-treated wooden floors and are equipped with twist locks at each exterior corner, allowing them to be lifted by special cranes and secured on ships, trucks, or trains. The edges of these rectangular and stackable receptacles are reinforced to withstand the pressure they experience during train vibrations, which are more intense than those on ships or trucks.

Containers bear a specific numbering system on their exterior to identify their owners, regardless of their cargo. Modern ports have scanners and readers to determine the appropriate placement for their transfer in multimodal operations.

Approximately 50% of existing containers belong to specialized leasing companies, 35% to shipping companies that own the vessels, and the rest to other companies. The average lifespan of a container is around 15 years. China accounts for 95% of container production.

The multimodal container has increased productivity in the transportation of goods. It has facilitated more efficient, simple, and cost-effective movement of items worldwide. For example, it is estimated that transporting a TV from Asia to Europe by sea costs US $10, while the shipment of a vacuum cleaner costs US $1, and transporting a can of beer costs US 1 cent. Currently, approximately 93% of non-bulk global cargo is transported in containers. Almost any manufactured product consumed by humans spends some time in a container, and about half of worldwide trade now takes place between locations over 3,000 km apart.

The costs of transportation are lower for maritime shipments, although the COVID-19 Pandemic gave space to an enormous rise in the prices, and the world is still recovering the price levels from before 2020. Shipment by train offers an option, but trains cannot transport the same cargo volume: by train it’s possible to move 50 containers, while a ship can take more than 20,000 containers at a time.

Regarding nearshoring vs offshoring operations, Mexico has the advantage of having thousands of kilometers of railway tracks that reach various points in the United States and Canada, which allows automotive and manufacturing industries to send their items to these countries in short periods of time.

Suppose your company is considering relocating to take advantage of nearshoring to Mexico, Frontier Industrial can offer industrial buildings for lease or industrial land for sale in the country’s main areas. Contact us to know more and develop your project.

-1.png)